-

-

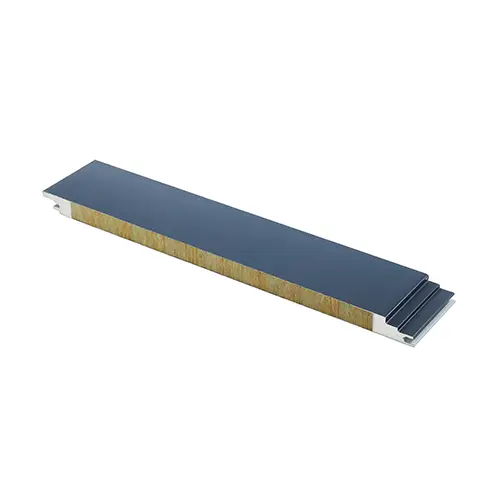

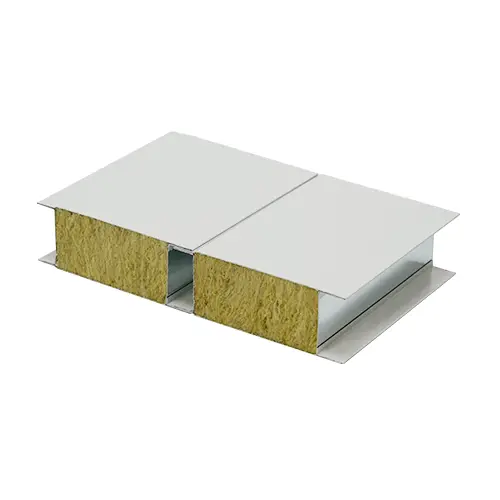

Energy saving metal enclosure system

The energy-saving metal enclosure system features efficient insulation, optimized design for reduced energy consumption, and enhanced operational efficiency across various industrial applications.Learn More -

Cold storage enclosure system

The cold storage enclosure system offers superior thermal insulation, robust construction, and energy-efficient performance, ideal for preserving perishables at optimal temperatures.Learn More -

Cold storage door

Cold storage doors provide excellent insulation, durability, and airtight seals, ensuring energy efficiency and temperature control in refrigeration environments.Learn More -

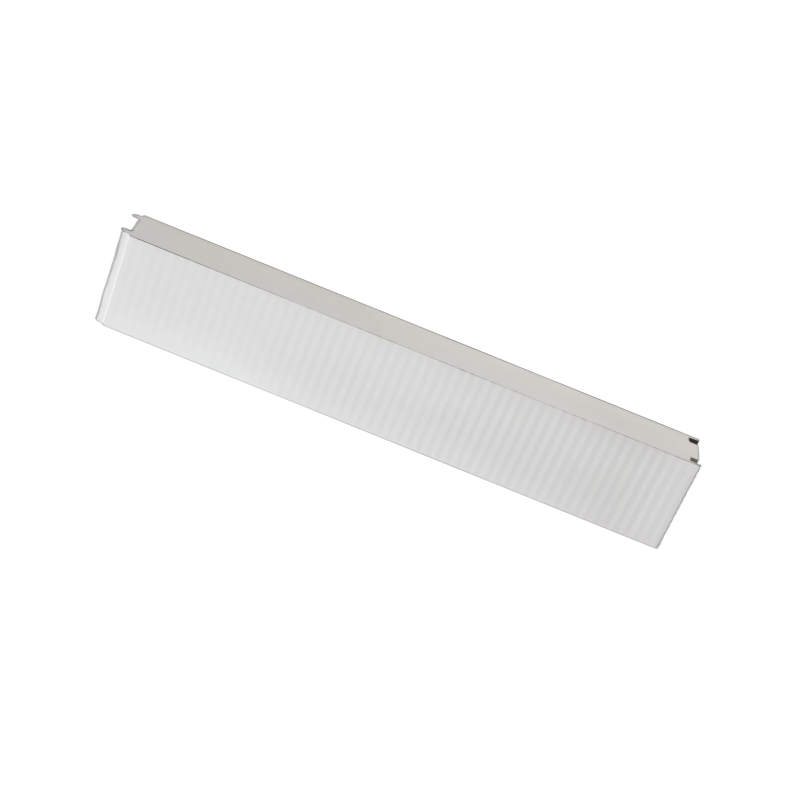

Clean Room System

Clean Room System is a controlled environment with low levels of pollutants, such as dust, microbes, and airborne particles.Learn More

Products -

-

-

-

-

09

2025

-

03

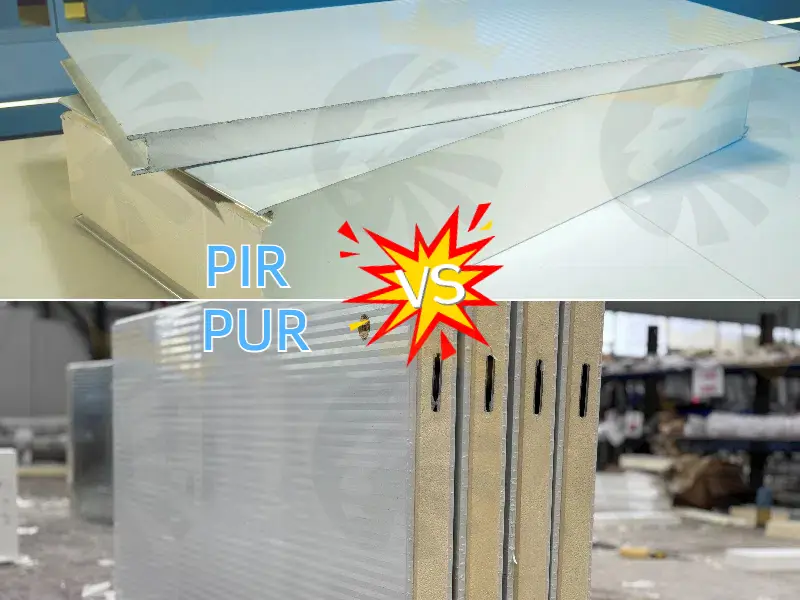

Uncover secrets: PIR cold storage panel V.S. PUR handmade panel

In the world of cold storage, choosing the right insulation is crucial. The battle between Polyurethane (PIR) machine-made panels and traditional PUR hand-made panels highlights key differences in production, performance, and efficiency. Let’s explore why LION CROWN is at the forefront of this transformation.

Pioneering Innovation in Cold Storage Panels

LION CROWN, a leader in polyurethane sandwich panels, is reshaping the industry with cutting-edge solutions. Specializing in PU cold storage panels, wall panels, and roof panels, LION CROWN ensures energy-efficient, eco-friendly, and durable products that embody their philosophy: “Good projects use LION CROWN energy-saving panels.”

Located in Zhaoqing City, Guangdong, the company boasts two fully automated polyurethane sandwich panel production lines, including a 42-meter double-belt hot press machine—one of the longest in China. This advanced setup guarantees superior foam density, adhesive strength, and insulation performance.

Machine-Made vs. Hand-Made Panels

Traditional hand-made panels rely on outdated manual methods, leading to inconsistent quality, poor adhesion, and reduced insulation. By contrast, LION CROWN’s automated production line delivers:

·Uniform Foam Density: Ensures enhanced insulation and structural integrity.

·Efficient Production: A single line produces up to 12,000 square meters daily.

·Superior Performance: Achieves a thermal conductivity as low as 0.019W/mK.

Safety First: Flame Resistance That Saves Lives

LION CROWN uses PIR foam, engineered at the molecular level for flame retardancy. Certified at B1-grade, the material self-extinguishes when the flame is removed, unlike traditional PU foam, which struggles to achieve similar fire safety levels. Tragic incidents, such as the "Hangzhou Ice and Snow World" and "Shanghai Fire," underscore the critical importance of using flame-resistant materials.

Insulation Matters: Energy Efficiency and Cost Savings

Poor insulation can lead to temperature instability, higher energy costs, and compromised product safety. LION CROWN’s panels feature a 97% closed-cell rate, minimizing heat exchange and ensuring optimal energy efficiency.

Traditional Methods Fall Short

Manual foaming techniques in traditional panels often lead to uneven density, hollow spaces, and weaker performance. Thermal conductivity ranges from 0.022 to 0.026W/mK, compared to LION CROWN’s superior 0.019W/mK.

Meeting the Demands of Large-Scale Projects

With intelligent, computer-controlled production, LION CROWN ensures error-free, high-quality panels at scale. Unlike manual methods, which are slow and labor-intensive, LION CROWN’s technology delivers rapid turnaround for medium to large projects.

Choose the Best for Your Cold Storage Needs

Whether you prioritize energy savings, safety, or efficiency, LION CROWN’s PIR cold storage panels stand out as the industry’s premium choice.

For more information, contact LION CROWN’s professional team—we’re always online to help you transform your cold storage projects!

Are you ready?

Start your project now!

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

CONTACT US

Room.302, No.8 Building, Nanshun Plaza, Jianping Road, Nanhai District, Foshan City, Guangdong Province, China