Zhuhai Gechuang Intelligent Component Factory and Supporting Construction Project

Area: 32000㎡

Project Overview

The project involved the installation of an energy-saving metal enclosure system for a newly constructed commercial office building in downtown Chicago. The goal was to enhance the building's energy efficiency, reduce operational costs, and achieve LEED Gold certification. The metal enclosure system was designed to provide superior thermal insulation, weather resistance, and aesthetic appeal while minimizing environmental impact.

Project Duration

The construction timeline spanned 6 months, from March 2023 to August 2023. This included the design phase, material procurement, installation, and final inspections. The project was completed on schedule, thanks to efficient planning and coordination among stakeholders.

Project Scope

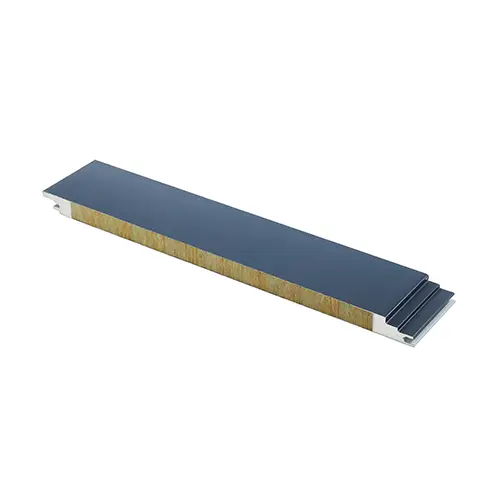

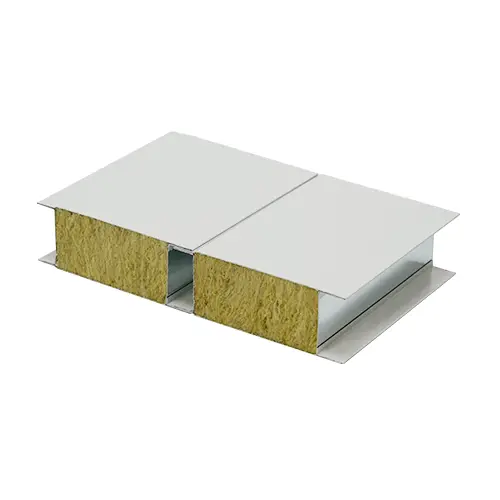

The energy-saving metal enclosure system covered the building's exterior walls and roof, totaling 15,000 square meters. The system consisted of insulated metal panels (IMPs) with a high-performance reflective coating to reduce heat absorption. Additionally, the design incorporated advanced sealing techniques to prevent air leakage and thermal bridging.

Construction Process

Design and Planning (March 2023)

Collaborated with architects and engineers to finalize the design of the metal enclosure system.

Conducted thermal simulations to optimize insulation performance.

Selected materials with high recycled content and low environmental impact.

Material Procurement (April 2023)

Sourced insulated metal panels and reflective coatings from certified suppliers.

Ensured all materials met energy efficiency and sustainability standards.

Site Preparation (May 2023)

Prepared the building's exterior surfaces for installation.

Installed a temporary weather barrier to protect the structure during construction.

Installation of Metal Enclosure System (June - July 2023)

Began with the installation of the wall panels, followed by the roof panels.

Used precision tools to ensure proper alignment and sealing of the panels.

Integrated ventilation systems to promote air circulation and reduce moisture buildup.

Quality Assurance and Testing (August 2023)

Conducted thermal imaging tests to identify and address any insulation gaps.

Performed air leakage tests to ensure the building envelope met energy efficiency standards.

Inspected the system for durability and compliance with safety regulations.

Project Completion and Handover (August 2023)

Delivered the completed project to the client, including documentation for LEED certification.

Provided a maintenance guide to ensure long-term performance of the metal enclosure system.

Results and Benefits

The energy-saving metal enclosure system significantly reduced the building's energy consumption by 30%, leading to lower utility costs and a smaller carbon footprint. The project successfully achieved LEED Gold certification, highlighting its commitment to sustainability. The building's occupants also reported improved comfort due to consistent indoor temperatures and better air quality.

This case study demonstrates how energy-saving metal enclosure systems can deliver both environmental and economic benefits, making them an ideal choice for modern construction projects.