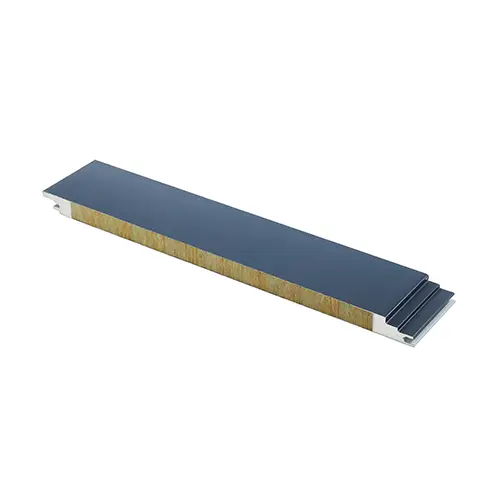

PUR cold storage insulated panel

Wall Panel Series

LION CROWN PUR cold storage panels are crafted utilizing PUR core material and are custom-manufactured in various sizes through mold-based production techniques. Locking devices are integrated and placed around the core panel during the manufacturing process, facilitating straightforward assembly. These panels can achieve a maximum length of 8meters,making them particularly suitable for small-scale and non-standard engineering projects. LION CROWN utilizes imported foaming equipment boasting a thermal conductivity of≤0.026/W(m·K)and a fire resistance rating of up to B2, guaranteeing exceptional product quality and performance.

Product Features:

- LION CROWN PUR cold storage panel is suitable for non-standard customization, and the size and thickness can be customized according to customer needs. And it is a prior choice for many small and non-standard engineering projects.

Let's Talk

Parameter | Surface | Material | ||

Steel | Aluminum | Stainless steel | ||

Thickness of exterior surface(mm) | Flat | 0.5-0.8 | 0.7-1.0 | 0.5-0.8 |

Square ware | 0.4-0.8 | 0.6-0.8 | 0.4-0.8 | |

Ripplet | 0.4-0.8 | 0.6-0.8 | 0.4-0.8 | |

Embossed | 0.5-0.6 | 0.6-0.7 | / | |

Width(mm) | 960 | Compressive strength(Kpa) | >150 | |

Thickness(mm) | 50/75/100/120/150/200 | Flame retardancy | B2/B3 | |

Core density (kg/m³) | 40±2 | Water | ≤3% | |

Length(mm) | The length can reach 12000 mm(single-sided pre-coated steel &single-sided stainless steel is recommended to be 6000mm or less) | Thermal conductivity | PUR≤0.026 | |

LION CROWN polyurethane sandwich panels are manufactured by advanced fourth generation fully automatic polyurethane sandwich panel continuous production

lines and a full set of Italian OMS foaming equipment. The production line has a length of 240 meters, using a core 5-component foaming process and applying a

new pentane foaming technology. The length of the hot press double track machine reaches 42 meters. The longer the double track machine, the more complete

the chemical reaction between polyols and isocyanates, and the stronger the molecular structure formed. This further improves the foaming density and uniformity of

the core material, ensuring the insulation performance and bonding strength of the panels.

Keyword:

Related Products

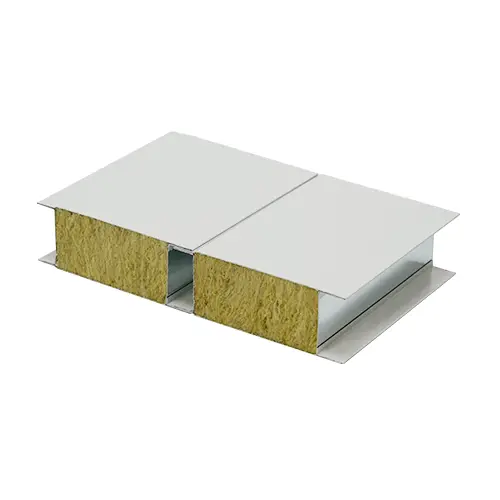

Rock wool acoustic exterior wall panel

LION CROWN perforated sound-absorbing sandwich panel combines regularly perforated metal steel plates with sound-absorbing materials inside the panel, providing excellent sound absorption and noise reduction effects. It also offers advantages such as fire resistance, environmental friendliness, and ease of construction. With a wide range of colors and various perforation patterns available, it can meet diverse decorative needs and sound insulation requirements.

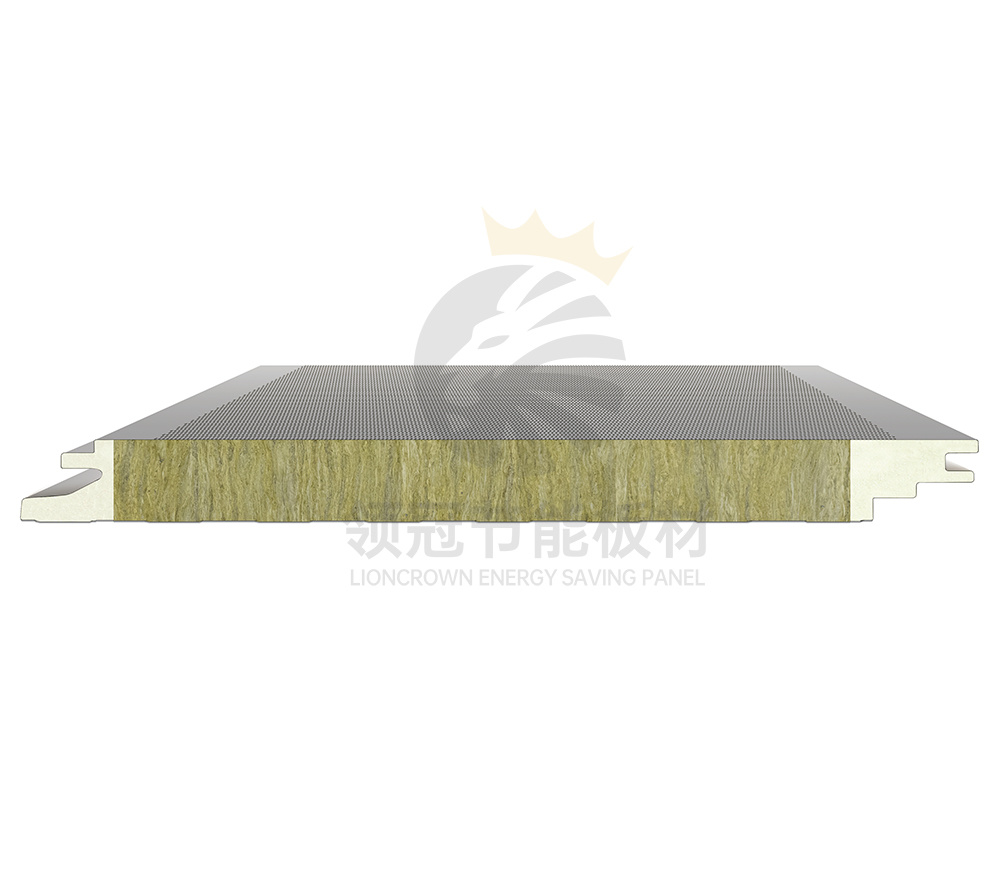

LION CROWN metal rock wool exterior wall sandwich panels adopt famous brand rock wool core materials with polyurethane edge sealing, is the best choice for energy-saving building materials.

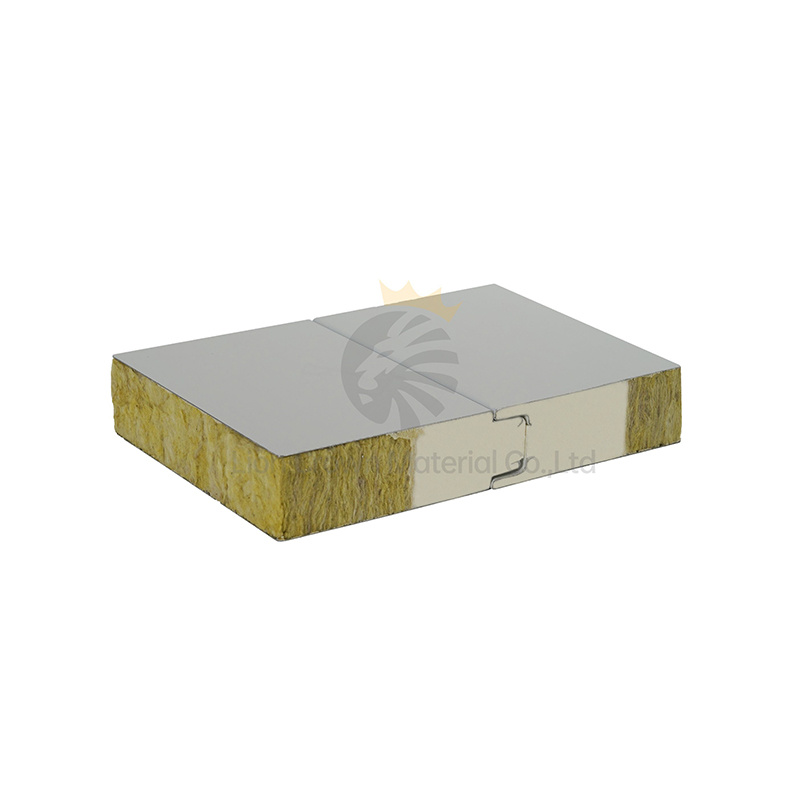

Rock wool interior paritition wall panel

LION CROWN metal rock wool interior wall sandwich panels adopt high quality rock wool core materials with polyurethane edge sealing, play an important role in modern insulated and eco-friendly building materials.

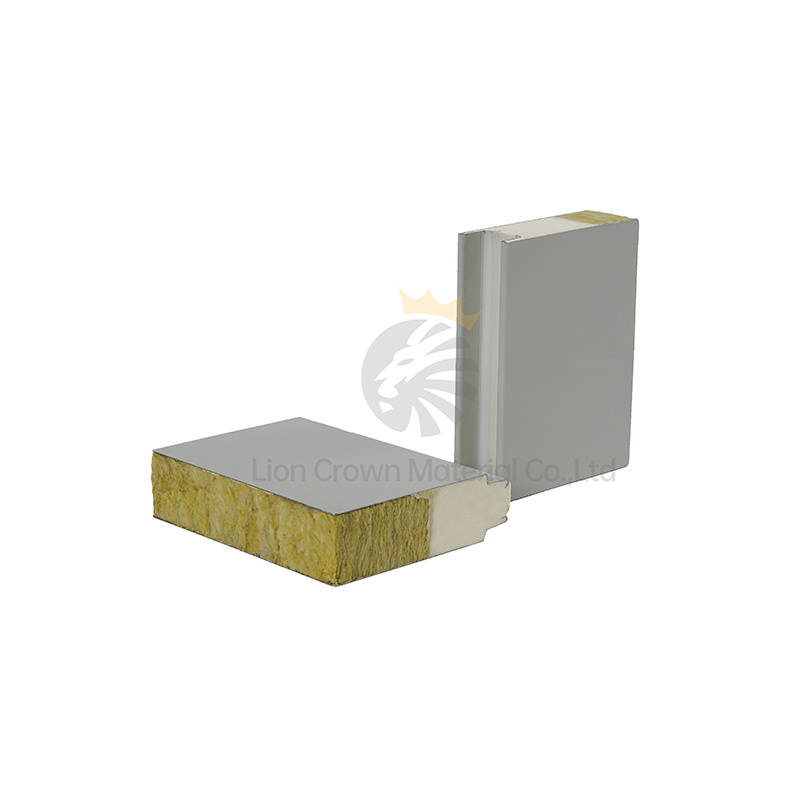

Polyurethane edge-sealed with Rockwool

LION CROWN metal curtain wall sandwich panels adopt exterior insulation to enhance energy efficiency, lower energy consumption, and shield buildings from moisture, thus extending their lifespan. Made with advanced insulating material of rock wool, which is the best choice for energy-saving building materials.